Following what goes on with oil and gas exploitation in and around Adrian, Michigan since 2013 - and how these events in our little city connect to the global environmental situation... - with the occasional sidetrack to other related environmental issues in Lenawee county, Michigan and how those relate to global issues.

Saturday, April 19, 2014

Air Pollution and Odor Nuisance Continues

Not really - but I wonder how much negligence has to be proven to an almighty energy company for the state to be able to fine them for their wrong-doing. My gut feeling is that the DEQ cannot do anything about it - Savoy could report to have problems forever and get away with it. This is absurd and unknown in most parts of the civilized world but not here in the State of Michigan, and The Land of the Free that should rather be called The Land of the free Corporations.

Saturday, April 12, 2014

Saturday, April 5, 2014

Flare Seems to be Mostly Down

Friday, March 7, 2014

Will the City, the County or the DEQ Do Something About the Flare?

Below are questions and comments that arose from the meeting at the County Health Department. Questions were answered by Kristie Shimko and Sersena White from the DEQ or followed from documents provided by Kristie Shimko. Some answers are edited or extended by me.

- Q: Are flares permitted to burn 100,000 cft per well and per day?

A: According to CAUSE 18-2007, a order of the DEQ Supervisor of Wells, the allowable amounts and duration of flaring within the Trenton and Black River formations are specified. These procedures were agreed upon in a discussion between the DEQ and the following oil and gas companies: Continental Resources, Inc.; West Bay Group; Savoy Energy LP; Trendwell Energy Corp.; Matrix Exploration & Development, LLC and Titan Energy, LLC.

“Gas that is not reasonably marketable may be flared. The volume of gas flared is restricted to 100 MCFGPD (100,000 cft gas per day) for a 40-acre drilling unit or 50 MCFGPD for a 20-acre drilling unit, which shall be the net volume of gas flared not including gas used for reasonable and necessary lease fuel purposes. The permittee of a well that is flaring gas shall, within 30 days of a letter of request from the Supervisor, submit to the Supervisor data necessary to determine whether the well can economically market gas. If data is not timely submitted to the Supervisor, the Supervisor may require the permittee to cease the flaring of gas. Based upon the data supplied by the permittee and other information available to the Supervisor, and after meeting with the permittee as necessary, the Supervisor or his authorized representative shall determine whether gas from the well can be economically marketed and shall inform the permittee in writing of that determination. Within 90 days of a determination in the affirmative, or at such later date as the Supervisor may specify, the permittee shall cease the flaring of gas from the well. If the permittee disputes the Supervisor's determination, the permittee may file a petition and request a hearing; but the filing of such petition shall not stay the effectiveness of the determination. If the Supervisor determines that gas from the well cannot be economically marketed*, the permittee shall be allowed to continue flaring gas at the rate specified above. Permission to flare does not grant an exception to any other required permits or approvals.

*Marketing of gas be deemed not economic when an operator provides reasonable evidence to the Supervisor that the cost to connect a well to a pipeline or facility for the transportation and processing of gas will take in excess of two years to pay out based upon the average monthly natural gas production sales.

Get the full PDF-document here. - Q: There is no permit needed to flare off natural gas for as long as it takes, even if the flare gas contains benzene and other toxic and cancerous compounds.

A: No answer by DEQ – I guess this answers that there is no additional permit needed as follows from 1.) above. My search for the name the industry uses for flares enclosed in open oil tanks, I found several commercial combustion tools that ensure better and cleaner burns (e.g. mrw-tech.com, abutec.com). It seems that the Michigan DEQ does not require such cleaner technologies. - Q: There should not be any odors (and no elevated levels of volatile/gaseous pollutants) from any well-burning flare, oil well, or oil pump. A well-burning flare should also produce no soot. Flares should be maintained so the burn at least 96% of the combustible compounds.

A: No odors should occur and should be reported. If odors occur it indicates a less than proper burning rate of at least 96% and thus more unburned pollutants that might not have an odor at toxic levels (such as benzene). The Witt Farm flare smells almost every day and is thus most of the time burning way below 96% efficiency. - Q: The current air quality application is only concerned with Savoy's plans to send off the currently flared gases to the tank farm on Tipton for commercial use?

A: Savoy applied for a permit to finally capture and market the gases coming in to the Witt Farm (Adrian 1-25) from currently 7 wells. The current air quality application is concerned with the proposed installation of any piece of equipment that will emit an air contaminant. And those pieces of equipment are a glycol dehydration unit and an internal combustion engine. The company is also proposing a refrigeration unit but it is totally enclosed and thus has no emissions to the ambient air. - Q: The current application might be held back because the presence of benzene, too much water and to high BTU. The levels of toxins that I received from you in a table are levels that only matter for the permit process of marketing gas - not for flaring?

A: The current application will be evaluated with respect to the presence of benzene in the gas intended to be marketed, its relative high water content and a higher than permissible BTU to determine if their proposal will comply with applicable rules. This might delay the marketing of the gas and keep the flare going. - Q: Flaring will still go on even after marketing the gas if there is more gas then can be send to commercial use or if there is a technical problem preventing to send off the gas?

A: The flare will remain at the site for any of the following reasons:

* flaring off gas in the event of an emergency

* flaring off gas for equipment maintenance

* it may possibility be needed as a control device to ensure compliance with a rule (this will be determined in the upcoming technical review). - Q: The DEQ does not and will not monitor the Adrian 1-25 (Witt Farm) flare and discouraged the county, city or an independent monitoring due to the difficulty to relate potentially high levels of benzene 500 meters away from the flare to actual health issues.

A: DEQ-AQD did not intend to discourage the county, city or any independent monitoring entity from pursuing air emission risk assessment monitoring. AQD only intended to inform those present of the types of details and the length of the project for conducting a risk assessment monitoring project. The allowed air emissions of benzene as identified in the air toxics attachment is 0.1 µg (micro grams = 1 millionth of a gram) per cubic meter of air at or beyond the property boundary on annual averaging time. An approved permit to install for regulated emission units at this site would require this limit is met.

Reference: Michigan Department Environmental Quality - Air Quality Division List of Screening Levels (ITSL, IRSL and SRSL) in Alphabetical Order. - Q: What are the costs for a well permit, a tank farm permit, a brine disposal permit? Are there any independent and unannounced water and air monitoring procedures done or initiated by the DEQ that Savoy has to pay for? If yes when? Baseline, every month???

A: The cost for an oil well/brine disposal well permit is $300. There is no cost for a tank battery [like Witt Farm or Adrian 1-25]. A permittee of a well shall submit secondary containment plans, for approval before construction of a facility. After construction completion and before the facility can be put in operation, the permittee must submit: a statement certifying that the facility was constructed in accordance with the approved plan; the results of initial pressure testing of the piping; approved spill or loss response and remedial action plan; a water sample to establish ground water quality. Testing of the flow lines and underground piping is required annually. Secondary containment (ground water) monitoring is required every six months. Savoy contracts the flow line pressure testing and ground water sampling to qualified, independent third parties. DEQ can and will collect soil, groundwater and/or gas samples if deemed necessary. - Q: How much money does Savoy have to put into an emergency escrow account to pay for the cleanup and containment of well, pipeline, or trucking spills?

A: Savoy has a $250,000 bond on file with the Office of Oil, Gas and Minerals. [This money will not reach very far in case of a major spill – and who will pay for the rest? I am sure that will be the tax payer…Another example of corporate irresponsibility and the principle of externalization that takes advantage of everything true and trustworthy and undermines what we all learned as kids: if you make a mess you clean it up!] - Q: Are there any drills and exercises between all involved agencies and departments to make sure that the emergency responders are well prepared to contain and cleanup spills and other accidents?

A: OOGM encourages the oil company to equip/relay knowledge of the wells and facilities with the local fire department/responders. [I guess this is a good thing but it does not seem to be reinforced and might not happen in most cases making emergency situation even more dangerous…] - Q: What are the rules about drilling wells close to rivers and lakes? I already know that pipelines up to 5 inches diameter do not need a permit to go under a river or through wetlands.

A: As long as the well pad does not encroach upon a river/lake, it can be constructed. As long as sediment does not enter the water/stream/lake, they can construct the drill pad. [This seems to also just waiting for an accident to happen that will leave many people without potable water – actually something we saw happening in West Virginia this year, and something that happens for many people in Texas, Colorado, Wyoming and other states where hydraulic fracturing (fracking) adds to the problems we are facing here in Adrian and SE Michigan.

Meeting at the Lenawee County Health Department

As previously reported, the Lenawee Health Department hosted an informal meeting on my request to discuss the health risks for citizens of Adrian and Adrian and Raisin Township imposed by the large flare (see below) on Witt Farm (Adrian-25). The meeting took place on Friday, February, the 21st.

The following people attended this meeting:

Patsy Bourgeois (Health Officer, Lenawee County Health Department), Martha Hall (Environmental Health Director, Lenawee County Health Department), Elise Garcia (Adrian Dominican Sisters), John Kuschell (Adrian resident, recycling activist), Jim Berryman (Mayor of the City of Adrian), Shane Horn (Interim Administrator of the City of Adrian), Sersena White (Senior Environmental Engineer, Michigan DEQ Air Quality Division), Terry Wright (Permit specialist, DEQ Air Quality Division), Kristie Shimko (Geologist, DEQ, Office of Oil, Gas, and Minerals, Lansing District Office, covering Jackson, Hillsdale and Lenawee Counties), Terry Collins (Lenawee County Commissioner for District 6: Westside of the City of Adrian and retired police chief of the City of Adrian), Amy Wassmer (Adrian resident and environmentalist), and Tom Wassmer (Assistant Professor of Biology at Siena Heights University and Environmentalist).

Q: What was the meeting about?

A: Health Risks of the Massive Flare Within City Limits

Q: What is a flare?

A: A flare is a way to get rid of “waste” gas in oil and gas operations. Instead of using perfectly useful and energy-rich natural gas, many oil and gas companies do not want to invest in the technology needed to capture and market the gas and rather burn it off. This is not only a waste but produces greenhouse gases warming up our planet unnecessarily, and also set free poisonous and cancerous by-products such as benzene (more below)

Q: Where is there a flare on Witt Farm ? – I do not see a flame!

A: The flare is enclosed (hidden) from the view in a empty oil container with the top removed. This is supposable done to avoid that people are reporting a fire, and to allow for a better burning rate (see below). However, I am not sure that it is (also) a psychological trick to avoid that people are realizing what happens and become aware what is done here to our health and the environment.

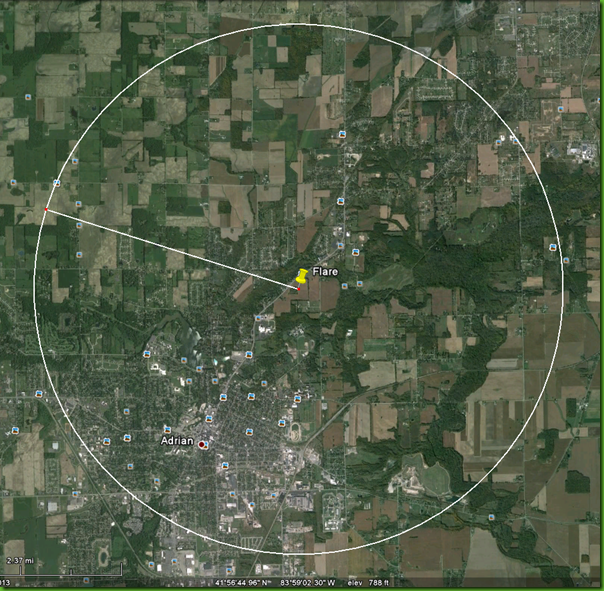

Location of the flare (pink rectangle)

But what is inside of the empty tank barrel is this: A massive flame that burns up to 770,000 cft of gas per day combining the maximum permitted amount of flare gases of currently 7 wells, which Savoy can further increase to a maximum of 10 wells - and then 1,100,000 cft of gas burned per day. In size and dimensions something like the open flare shown below:

If this flame burns at an efficiency of 96-100% then all is good. A minimal amount of methane, which is 100x as bad as a greenhouse gas as carbon dioxide and also minimal poisonous and cancerous hydrocarbons such as benzene are emitted. BUT, flares rarely burn at this efficiency due to winds and inconsistent flow rates of the "waste" gas itself. The consequence is a more orange flame with more soot (which you cannot see or cannot see very well in a enclosed flare) but also bad odor. If a flare smells then it is NOT burning at high efficiency. Some of this smells indicate that more methane escapes uncombusted, which makes the impact of a flare on global climate change worse. Much more concerning than bad odor are the higher concentrations of poisonous and cancerous hydrocarbons such as benzene that most people cannot smell at these concentrations but they can still cause short-term and long term health problems (see below).

Before being burned - the gas contains most probable (if Savoy is honest) the below components. In March 201, shortly after establishing the flare on Witt Farm (Adrian 1-25), Savoy Energy took a sample of the gas flared at Witt Farm (Adrian 1-25) and send it to a lab in Traverse City. I am puzzled that Savoy was not required to have the DEQ take the sample and send it to DEQ’s own environmental laboratory via a costly “Chain of Custody” to guarantee that it is the unhampered sample taken on location that arrives at the lab. This is the costly procedure every citizen has to go through to have air samples tested – why does the same rule not apply to a well-off company? However, the analysis still shows the presence of toxic and cancerous compounds such as BTEXs (benzene, toluene, ethylbenzene, and xylenes), most importantly benzene. Below are the analytical results for the sample(s) received by SPL on Thursday, March 28, 2013.

Q: The amount of benzene and other pollutants is surely too low to be concerned – otherwise the authorities would not allow flaring?

A: Unfortunately, local and regional authorities have no say in these matters and the DEQ and EPA are giving the oil and gas industry still unprecedented rights or have no legal tools to ask those industries to be more responsible. There is little information and research out there as these industries are very powerful and keep politicians, the court system, and even independent science out of their business. I already cited the exceptional study by James Argo in another blog post. Even in a well-burning flare, the following amounts of chemicals were released:

| On site characterization | Mg/m3 | Thermal Absorption > 10 mg/m3 | mg/m3 | Solvent Extraction > 10 mg/m3 | mg/m3 |

| Hydrogen | 20 | Pentane | 12.8 | Subst benzene | 9.83 |

| CO | 15.7 | 3-penten-1-yne | 19.3 | Azulene | 21.2 |

| CO2 | 4890 | Benzene | 144.5 | Subst benzene | 11.47 |

| Carbon | 54.2 | 1,5-hexadiyne | 48.2 | Naphthalene | 99.39 |

| Methane | 103.8 | Methyl benzene | 27.5 | 2-methyl naphthalene | 9.25 |

| Ethylene | 29 | Ethyl benzene | 13.7 | 1-methyl naphthalene | 6.18 |

| Acetylene | 53.7 | Ethynyl benzene | 94.8 | 1,1'-biphenyl | 58.7 |

| Ethane | 9.9 | Ethenyl benzene | 82.1 | Biphenylene | 42.81 |

| C3 HC's | 11.7 | Benzaldehyde | 18.7 | 1H phenalene | 21.01 |

| C4 HC's | 6.4 | Phenol | 26.4 | 9H fluorene | 41.09 |

| Benzene | 116.5 | Naphthalene | 88.7 | Phenanthrene | 10 |

| Toluene | 18.2 | 1,1'- biphenyl | 16.1 | Anthracene | 42.11 |

| Xylenes | 29.8 | Biphenylene | 19.1 | Fluoranthene | 51.35 |

| Styrene | 75.5 | Acenaphthalene | 23.2 | Pyrene | 32.37 |

| Ethynyl benzene | 79.6 | 4-methyl; pyrene | 9.1 | ||

| Naphthalene | 77.2 | 1 methyl pyrene | 8.4 | ||

| Other HC's | 128.5 | 38 Other HC's | 132.8 | Benzo(ghi)fluora nthene | 10.18 |

| CE | 65.0 % | Cyclopenta(cd)- pyrene | 29.77 | ||

| Benz(a)- anthracene | 17.33 | ||||

| 48 Other HC's | 94.47 |

I just want to focus on benzene (highlighted in red) as this is really bad stuff.

116.5 mg benzene/m3 when the gas is flowing at 6 m3/min in a sweet gas flare or 699 mg benzene released per minute. The authors find that the sweet gas flare has a maximum benzene concentration of 0.06 µg/m3 at about 500 m from the flare and measurable amounts at 5 km. These values are based on much smaller flares. The one on Witt Farm is permitted to flare up to 1,100,000 cft of gas per day – this would mean about 3.6x as much as the standard flare used in Argo’s calculations resulting in a benzene concentration of 0.22 µg/m3 at about 500 m and 0.09 µg/m3 at 5000 m. This is just below a lifetime risk of 1:1,000,000 for adult leukemia corresponding to an annual average benzene concentration of 0.096 ug/m3. Again this assumes 96-100% combustion rate (Values from Argo 2001, adjusted to likely concentrations and flow rates of the Witt Farm flare).

Combustion efficiency (CE) in a flare is severely affected by wind. Flares burning waste will only operate at

95+% if winds are less than about 2 kph. Winds of 25 kph will cut the CE to below 55-65%. In Adrian it is unlikely to have winds below 2 kph for at least 90% of the year! Enclosed flares are a little better but the frequency of bad odor from the flare confirms that it is most of the time NOT burning very well. Therefore the estimated concentration of benzene in the plume (wind direction) is most likely above the acceptable maximum value of 0.096 µg/m3 over at least 5 km from the source and an estimated peak value of benzene at about 500 m of about 4.8 µg/m3 or 50 X the acceptable maximum. This means: There might be an elevated risk for cancer may be present in the first 2.5 to 5 km from the flare. Residents in this zone have the potential to be affected by benzene exposure (described below). This concentration of benzene is below the odor threshold for most people (values and text passages from Argo 2001, values are representative for the Witt Farm as well).

The flare on Witt Farm and the 5km radius around the flare in which to expect health impacts due to benzene alone. At least 15,000 people live within this circle.

Q: What are the health risks of benzene exposure?

A: Benzene is a systemic toxicant in humans at any concentration and a cause of aplastic anemia (deficient red blood cell production). The major effect of benzene in the body is depression of bone marrow leading to pancytopenia, (a general depression of erythrocytes (red blood cells), leukocytes (white blood cells) and thrombocytes (platelets)). A widespread reduction in erythrocytes in a population will lead to a general increase in morbidity (Argo 2001).

Benzene is a known human carcinogen, causing leukemia; it is non-mutagenic. An annual time weighted average concentration (TWA) for a risk of 1 in a million is an annual average concentration of 0.096 µg/m3.

The odor threshold (threshold is the concentration when an average person becomes aware of an odor) of benzene is 4.5 mg/m3 and the odor is described as sweet. An average person will become aware of the presence of benzene at a concentration 4500 / 0.096 = 46,800 x maximum acceptable value for annual exposure of a risk of 1:1,000,000. An average person can be at risk of leukemia and never be aware, take steps to protect or otherwise act in defense of their health and integrity (Argo 2001).

Increased morbidity and elevated risk of leukemia is everywhere possible for residents within 5 km under these conditions. Those most at risk of long-term health effects are persons under age 30 (Argo 2001).

Further Information can be found using the below literature:

- D'Andrea MA, Singh O, Reddy GK. 2013. Health consequences of involuntary exposure to benzene following a flaring incident at British Petroleum refinery in Texas City. American journal of disaster medicine 8(3):169-79. Abstract on PubMed

- D'Andrea MA, Reddy GK. 2014. Health Effects of Benzene Exposure among Children Following a Flaring Incident at the British Petroleum Refinery in Texas City. Pediatric hematology and oncology 31(1):1-10. Abstract on PubMed

- Argo J. 2001. Unhealthy Effects of Upstream Oil and Gas Flaring. Sydney, NS, Canada: SAVE OUR SEAS and SHORES (SOSS). Available from: http://www.sierraclub.ca/national/oil-and-gas-exploration/soss-oil-and-gas-flaring.pdf

Q: What can we do to make sure that we are not getting sick from this benzene exposure?

A: Please refer to my next post in which I will summarize the outcome of the meeting.

Central Processing Facility (Tank Farm) on Witt Farm (Adrian 25)

Thursday, February 27, 2014

DEQ: Flares and Pumps Should Not Have Bad Odors

Contact details:

Kristy Shimko

Geologist

Covering Jackson, Hillsdale and Lenawee Counties

Michigan DEQ

Office of Oil, Gas, and Minerals

Lansing District Office

phone: 517-242-6847

Email: ShimkoK@michigan.gov